Indirect Cooling System

- Overview:

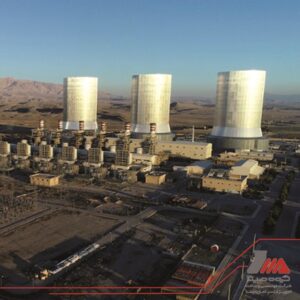

The exhaust steam of low-pressure (LP) turbines of thermal power plants needs to be converted into a fluid inside the condenser. Hence, there is always a challenge ahead for choosing between the following three types of condensers: air cooled (ACC), surface, or jet. In surface and jet condensers, the returned cool water from (wet or dry) towers can supply the needed energy for vapor to liquid phase change. Due to the importance of reducing water consumption, choosing a dry cooling system has become one of the major priorities, especially if the power plant is located in the central regions of Iran and away from water resources. It is possible to use the combination of a Heller dry cooling tower and a surface condenser as the main cooling system of the power plant, however, the most suitable technical and economical solution is to use a combination of a jet condenser and a Heller dry cooling tower. The incoming warm water to the Heller dry cooling tower and its heat exchangers (also called delta) leads to warming up the air inside the tower. The heated air inside the tower has a lower density and the difference of the density that it has compared to the higher layers creates an upward buoyancy force. This eventually leads to the cool air being sucked into the tower, going through finned heat exchangers, heating up, and exiting from the top of the tower. The height of towers is accordingly designed high

so as to strengthen this natural driving force. Depending on the volume of inlet hot water flow to the towers, the production capacity of the power plant, and the ambient temperature, it is necessary that the water be cooled between 8 and 12 degrees Celsius.

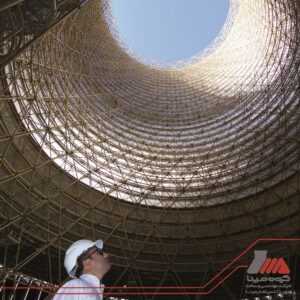

Creating a proper sealing system by using aluminum sheets can help better achieve this goal. The sealing seeks to prevent air leakage to the inside of the tower. So it is necessary to be equipped with the knowledge required for designing, constructing, and installing this structure.

Only a few engineering companies can operate in this field because of the complexities of constructing and installing this cooling tower along with the related considerations for carrying out its foundation. Sepahan MAPNA Engineering & Equipment Manufacturing Company is the only company inside the MAPNA Group that can supply, manufacture, and install this type of great metal structure.

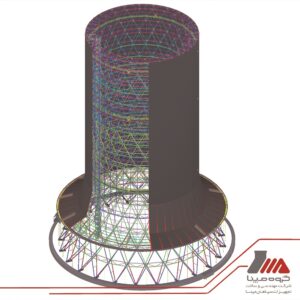

The implemented designs of Sepahan MAPNA Engineering & Equipment Manufacturing Company for cooling towers are of space structure types. This design makes the project’s construction and implementation completely different compared to similar projects. This structure makes modeling conditions more complicated and increases the accuracy of the parts. It also has other advantages, including better resilience against dynamic loads such as those created by earthquakes or strong winds. Furthermore, the material used for this type of structure is almost 100% recyclable.

In addition, the company has managed to localize the technical knowledge related to designing, supplying, and installing dry, wet, and hybrid cooling systems. Accordingly, the company is fully ready to provide engineering services in the field of design, construction, and supply of various cooling systems.

Technical Characteristics

Weight: 2,250 tons

Material: S235JR

Dimensions: Diameter of tower’s lower part is 110 meters and that of upper part is 70 meters

wholevivo.com https://www.greatiphone.de/die-perfekte-kombination-aus-schutz-und-funktionalitaet-die-apple-iphone-xr-huelle-mit-magnetischem-ringstaender-in-rot over here

Past projects

| DRY COOLING TOWERS (HELLER) | unite | Weight Unit | year |

| JAHROM | 3 | 1450ton | 98 |

| HAMEDAN | 1 | 2250ton | 97 |

فارسی

فارسی Français

Français العربية

العربية