Auxiliary Boilers

- Overview:

In line with the MAPNA Group’s strategies and with the aim of better integration of design and supply from domestic firms, the mission of designing and manufacturing heating and startup auxiliary boilers of power plants has been given to Sepahan MAPNA Engineering & Equipment Manufacturing Company. Heating boilers are used to provide the required energy for equipment and fuel tanks during cold seasons. Meanwhile, startup boilers, which generally have a higher capacity and tonnage, are used as a primary steam supplier during startup for major equipment such as hogging ejector and main boiler deaerator of power plants.

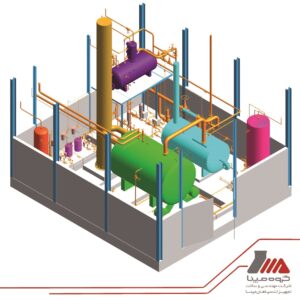

Due to the capacity and working pressure, these boilers are of Fire Tube type. A host of other auxiliary equipment is also put beside the main boiler inside the boiler house, including deaerator, storage tank, blowdown tank, and fuel tank.

Equipped with the technical knowledge for designing and engineering and using precise calculations and design codes developed in the R&D department, Sepahan MAPNA Engineering & Equipment Manufacturing Company is capable of designing boilers’ thermal and mechanical features as well as superheaters and all the auxiliary equipment with the capacity of 30 tons and the working pressure of 35 bars that can superheat the steam up to 50 degrees Celsius. The company also manufactures fire tube boilers of 3 pass and wet back types, that have high thermal efficiency, based on boiler manufacturing standards such as BS-2790-1992 and EN 12953 and Iran’s national standard requirements. Furthermore, the company has managed, for the first time in Iran, to attain the knowledge of designing and manufacturing superheaters that are integrated with boilers or external with a separate torch; these devices can produce steam with superheat or high temperatures.

The company enjoys the capability of designing and manufacturing all the equipment according to the needed steam capacity. A detailed thermal, mechanical, and metallurgical analysis of the equipment along with a central and integrated control system guarantees the required temperature and pressure for consumers that each has different needs and conditions.

Sepahan MAPNA Engineering & Equipment Manufacturing Company also carries out the designing and manufacturing of boiler houses and equipment.

Past projects :

Sepahan MAPNA Engineering & Equipment Manufacturing Company :

Designing and manufacturing 3-ton heating boiler with 10 bar working pressure for use in testing power plant ejectors inside the company

Zanjan-2 Combined Cycle Power Plant

Designing and manufacturing startup boiler with a capacity of 24 tons per hour, 11 bar pressure, and 250°C temperature

Designing and manufacturing heating boiler with a capacity of 5.6 tons per hour, 5 bar pressure, and 160°C temperature

Sabzevar Combined Cycle Power Plant

Designing and manufacturing startup boiler with a capacity of 24 tons per hour, 10 bar pressure, and 250°C temperature

Designing and manufacturing heating boiler with a capacity of 5.6 tons per hour, 5 bar pressure, and 160°C temperature

Torbat-e Heydarieh Combined Cycle Power Plant:

Designing and manufacturing hybrid boiler (heating and startup) with a capacity of 22 tons per hour, 10 bar pressure, and and 250°C temperature

Khorramabad Combined Cycle Power Plant:

Designing and manufacturing startup boiler with a capacity of 21 tons per hour, 9 bar pressure, and 230°C temperature

Latakia Combined Cycle Power Plant (Syria):

Designing and manufacturing startup boiler with a capacity of 9 tons per hour, 9 bar pressure, and 230°C temperature

Zarand Power Plant:

Designing and manufacturing heating boiler with a capacity of 5.5 tons per hour, 5 bar pressure, and 160°C temperature

Do-Kuhe Power Plant:

Designing and manufacturing heating boiler with a capacity of 2.2 tons per hour

فارسی

فارسی Français

Français العربية

العربية