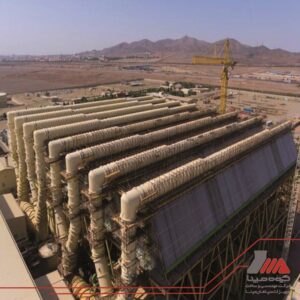

Direct Cooling System

- Overview:

Here is how this system works: the outgoing steam of the lower part of the steam turbine is directly transferred to a group of pipes named Tube Bundle through a steam distribution system. These pipes have blades on the outer surface and when they are exposed to the airflow of the fans, the steam distills. There is actually no separate condenser in this system as the same group of pipes plays the condenser’s role. The cooling air passes over the tube bundles and absorbs the latent heat of the steam, leading to distilment inside the pipes. Steam flows down from the tip of the A-shaped pipes and is distilled along the path. The distilled fluid is collected at the end of the path and transferred to a relevant tank. Gases that cannot be distilled are returned to the cycle by the exhaust system. The collected fluid is also returned to feed the system by a water pump.

The cooling airflow of this system is created by axial fans that are installed horizontally. There are two conventional methods for a fan control system: a two-speed motor and a VFD frequency converter. High efficiency, reliability in all weather conditions, and fast and secure installation are among the advantages of this system

The Company’s Products in This Field:

Turbine Exhaust Duct

Dry cooling systems, in general, need to be installed in power plants so that there will be no limitation with regard to the inlet air. ACC systems are the only cooling systems that require to be close to turbine construction so as to minimize the pressure drop between the steam turbine and the air condenser. The height of the structure that houses the ACC system depends on various parameters including ambient temperature and the wind speed of the region. The weight of the structure is about 1,500 tons.

Steam Distribution System

The system is tasked with carrying the steam from low-pressure sections of the turbine to condensers and distributing the steam to tube bundles. The weight of this equipment is about 750 tons.

Distilled Fluid Collection System:

The system comprises tanks that collect distilled fluid. After collection, the fluid is directed toward the heat recovery boiler and it will move the turbine after being converted into superheated steam. The weight of this tank is about 50 tons.

سیستم جمع کننده سیال تقطیر شده

Structure

- Past projects

weight | year | |||

KAHNOJ | 1 | – | 1500 ton | 94 |

ORUMIEH | 3 | – | 4500 ton | 96 |

فارسی

فارسی Français

Français العربية

العربية