DISTILLATION TOWER

Overview:

Distillation tower is a tool to physically separate liquid mixtures and distillate them and operates based on the difference between boiling points of liquids that exist in the mixture.

Liquids, in this process, are separated into their components according to their volatility.

When a liquid mixture that has different components, like oil, is poured into the distillation tower, these components are separated according to the difference in their boiling points.

This tower is built on two scales: a small-scale one for laboratories and a large-scale one for industrial refineries. The laboratory type is designed for operation on a small number of mixtures and is made of glass.

However, the industrial type is designed for petrochemical processes, oil, natural gas, fermentation, and making coal tar processes.

The most important use of distillation towers relates to the oil industry when it acts to separate oil’s various hydrocarbons based on their volatilities because crude oil is a complex multi-component compound.

Heavier hydrocarbons have higher boiling points, and lighter hydrocarbons with lower boiling points record a sooner departure from the tower.

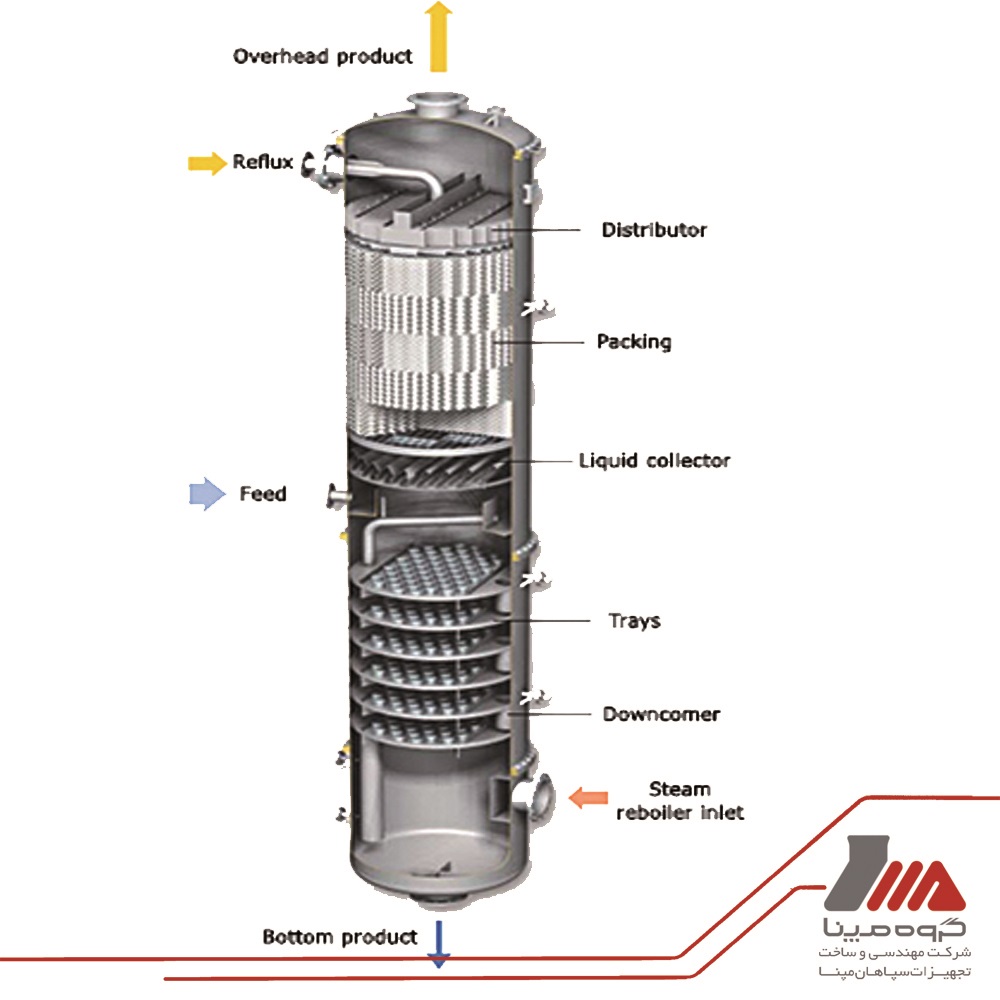

Distillation tower in general has four main segments:

Tower: Industrial Distillation Tower, vertical cylindrical columns with a diameter ranging from 65cm to 6m and a height between 6m to 60m.

Reboiler system

Condensor system

Auxiliary equipment including different types of controller systems, heat exchangers, pumps, and tanks for collecting the product.

Due to the experiences of Sepahan MAPNA Engineering & Equipment Manufacturing Company in similar projects such as wind turbine towers, the company is capable of supplying and manufacturing this product as well.

فارسی

فارسی Français

Français العربية

العربية