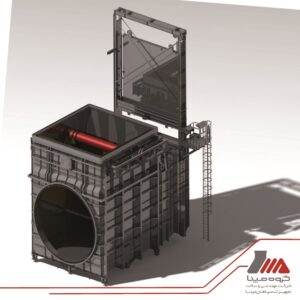

Diverter Damper

Overview:

Increasing the efficiency of current gas power plants through converting them to combined cycle one is among the main strategies of the country in the energy sector. The possibility of reusing the outgoing heat of the gas turbine through a heat recovery steam generator (HRSG) and a steam power plant unit helps enhance the power plant’s efficiency. Accordingly, the diverter damper system, as a connector of gas and steam turbines, is of great importance in combined cycle power plants. The most important roles of this equipment have been named below.

Diverter Damper Functions:

- Guiding the exhaust smoke to boiler or exhaust (outdoor environment)

- Directing the exhaust gas toward boiler or bypass stack

- Adjusting the exhaust gas flow to the boiler while the boiler is starting up or running back

- Preventing leakage of hot gas flow to HRSG environment or toward the bypass stack

- Ensuring that hot gas flow is not leaked to the boiler by using guillotine dampers while doing repair on boiler

Tehcnical Characteristics:

The part is made of various carbon, steel, and special alloys materials that can function in high heat plus proper insulation and interior protection covering

Dimensions:

As the diverter damper is installed on the diverter box and the entrance of the boiler and exhaust, the approximate dimensions of the project directly depend on the characteristics of the boiler and the gas turbine model.

Other specifications:

The diverter damper project includes the largest and most efficient movement mechanisms in combined cycle power plants. The equipment has a pair of hydraulic systems with the ability to change the angle to 90 degrees which guide the turbine’s hot gas towards the exhaust or boiler; the amount of incoming gas to the boiler can be adjusted by changing the angle of the diverter damper gate. The Air Sealing System keeps temperatures of surfaces of exhaust valves and boiler balanced while leading to increased efficiency of the diverter damper system and sealing process. Guillotine dampers make sure that the path of hot gas to the boiler is sealed by using vertical and horizontal movements powered by mechanical conductor systems.

Capabilities of Company:

Sepahan MAPNA Engineering & Equipment Manufacturing Company has more than 10-year experience in manufacturing this equipment and is capable of designing, manufacturing, and installing similar equipment with different weights and dimensions for gas power plants of different capacities.

فارسی

فارسی Français

Français العربية

العربية