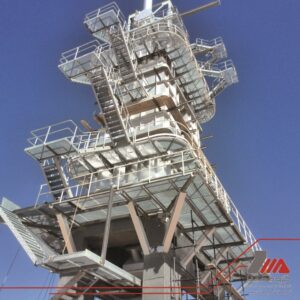

LIME KILN

- Overview:

Lime is used in various industries including steel, copper, construction, road construction, asphalt, cement, brick, glass, agriculture, dam construction, water industry, sugar, paint, rubber among others. Most operating kilns in Iran are of the rotary type that consumes 2 to 3 times more energy per ton of product compared to double shaft kilns.

In a bid to reduce energy consumption and improve the efficiency of this equipment, Sepahan MAPNA Engineering & Equipment Manufacturing Company decided to design and manufacture a double shaft lime kiln according to Switzerland’s MEARZ technology for the first time in Iran.

With a nominal capacity of 150 tons per day, the machine offers products in various granulations while their quality is endorsed by the steel and mining industries.

Limestone is typically provided in the size of 40-80mm with a total tonnage of 300 tons.

This kiln is powered by coke or mazut and if gas is used as the fuel, 100 cubic meters of gas is used for the calcination of each ton of lime.

Each cycle of the kiln takes between 10 to 15 minutes. After the cycle ends, the reversal time (shaft cycle replacement) takes about 70 seconds.

After gas and air art cut, the inlet valves of the limestones and the outlet valve of lime are opened and the shaft where the heating process takes place is charged with stones while the produced lime is discharged from exit valves.

The process of this reaction is as follows:

CaCO3+HEAT → CaO+CO2

Technical Characteristics:

- Material: Carbon steel, stainless steel, refractory materials, thermal insulators

- Dimensions: 4*8*38(H) meters

Past projects :

KILNS FOR SOFT-BURNT LIME | unite | power | year |

YAZD | 1 | 150 ton | 92 |

Year | Power | Unit | Kilns for soft-burnt lime |

2013 | 250 tons | 1 | Yazd |

فارسی

فارسی Français

Français العربية

العربية