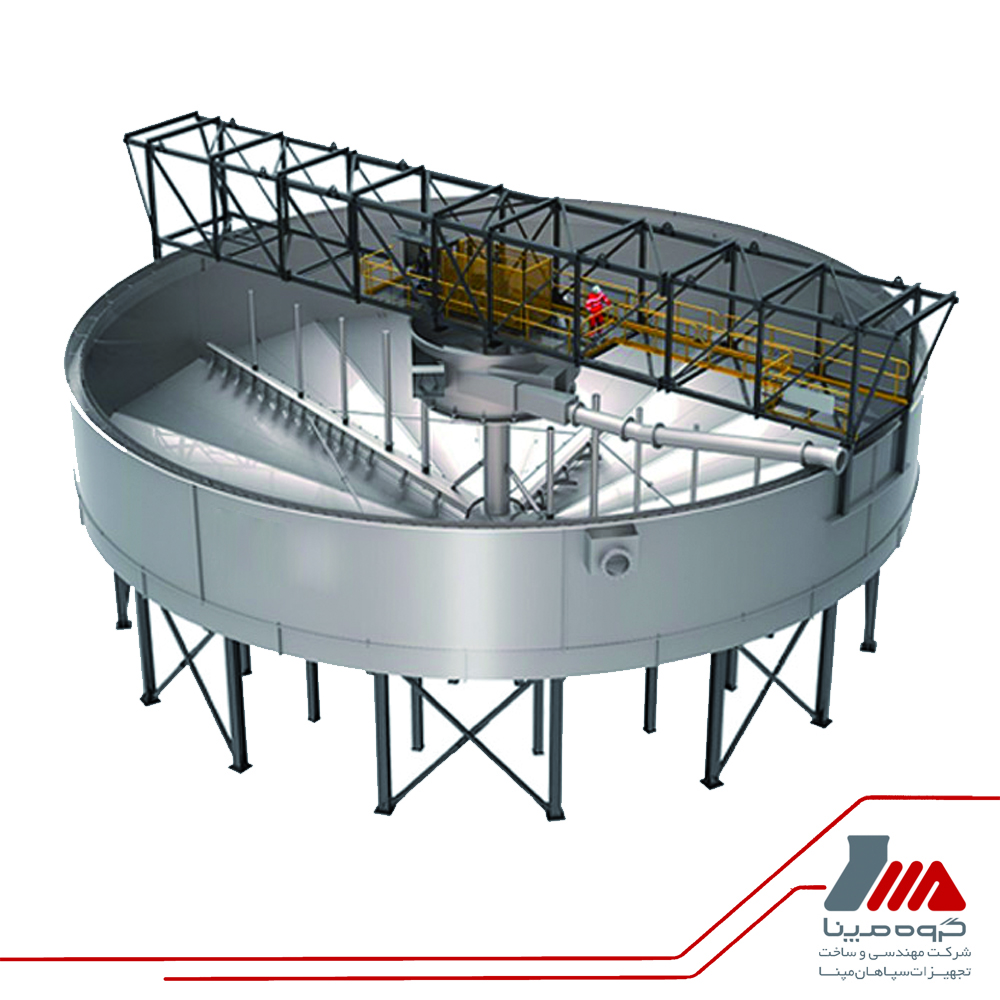

Thickener System

- Overview:

The process of recycling industrial water in mining industries and reusing it has always been one of the most important requirements of our country in this section. Therefore, due to the lack of groundwater resources, the staggering cost of water extraction, and the existing pollutants in the wastewater of mining industries, it is inevitable to use thickeners.

What is thickener?

Tickner is designed and manufactured to treat wastewater produced by mines such as iron, copper, aluminum, as well as ceramic factories, and stone cutting and sand washing units.

As the wastewater of these industries contains large amounts of particles and TSS, it is possible to use the treated water in the production line by designing and installing a thickener; this solution can save costs of operating production units.

The inlet wastewater bears a high amount of solids due to the density difference between the particles and the liquid, these particles settle and are then removed from the bottom of the tank in the form of condensation flow or underflow. The treated water exits the tank in the overflow process.

Different types of thickener

- Ordinary thickener

- Plate thickener

- Lamella thickener

- Conical thickener

- Deep thickener

- High rate thickener

Sepahan MAPNA Engineering & Equipment Manufacturing Company has a good record in related projects and is able to design, supply, and manufacture this equipment as well.

فارسی

فارسی Français

Français العربية

العربية