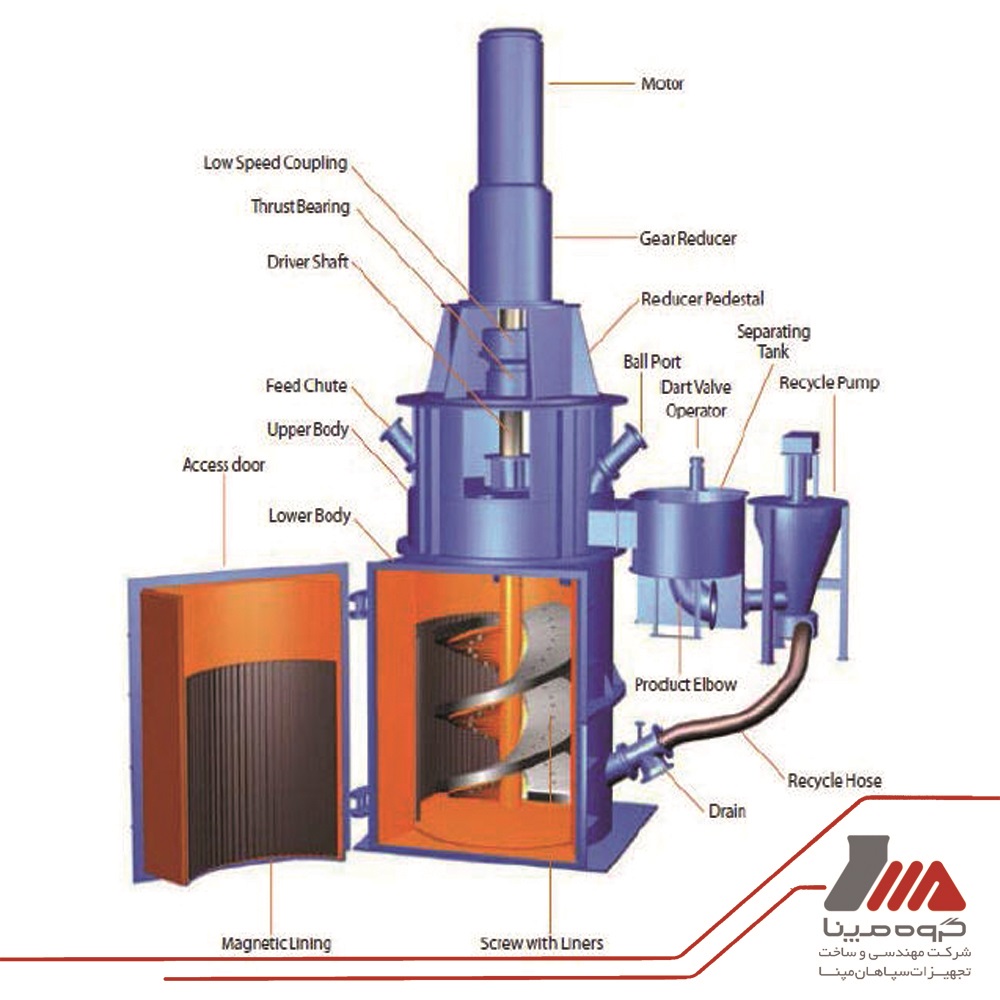

VERTICAL GRINDING MILL

Overview:

Vertical grinding mills have different functions and are mainly used to grind mineral material.

They operate in wet and dry conditions as well as continuous and periodic modes.

The mixture of materials and slurry is continuously fed into the machine through the top inlet.

A set of discs that rotate by using a propulsion motor pushes crusher rollers upward. Affected by centrifugal force, the rollers move to the sides before gravity takes them to the bottom of the chamber.

These up and down moves of the rollers lead to a significant amount of collisions that crushes the input material.

The bottom-up pressure in the main tank is produced due to two reasons; the upward movement of the spirals and the pressure of the return pump from the lower inlet.

This pressure has two advantages: the first is that the pressure forces the ground material that is smaller and lighter to the top, hence preventing unwanted crushing.

Next, it does not allow feeding particles that are smaller than the standard size.

Fine particles are directed towards the vortex granulator through the outlet.

Smaller and lighter particles exit the cone but the larger and heavier ones sink into the bottom and are pumped out along with rejected larger hydrocyclone particles (from upper filters).

The resulting slurry is again fed into the machine’s tank so that necessary crushing takes place.

This machine has applications in the following industries:

- Producing Zinc Oxide

- Producing needed materials for leaching operation

- Producing Magnesium Oxide

- Producing Iron powder

- Producing Aluminium powder

- Producing Copper powder

- Producing Nickel powder

- Producing Zircon powder

- Producing Lead-Zinc powder

- Producing Gold and Silver powder

- Producing powders of different colors

- Producing powders of different drugs

Considering the experiences of Sepahan MAPNA Engineering & Equipment Manufacturing Company in similar projects, the company is capable of supplying and manufacturing this product.

فارسی

فارسی Français

Français العربية

العربية