DUST COLLECTING EQUIPMENT

- Overview:

An industrial dust collector is a device that includes an industrial ventilator and aims to collect dust and particles that are produced during industrial processes in various working environments. Industrial dust collectors are specifically used to collect dust resulting from different production procedures in various industrial environments.

In addition to disrupting the production process and undermining the optimal performance of the equipment, dust is also a threat to employees’ health as it causes different diseases. The volume of dust and particles is high while their size is very small and hence, they can enter the lungs and even damage the respiratory system. These particles are sometimes toxic, however, the industrial dust collector can be installed to collect the produced dust before their release into the environment.

The equipment is sometimes referred to with different names such as dry dust collector and central dust collector.

Advantages of using industrial dust collectors:

In a workplace where a central channeled system is in place, if there is a need to change the place of machines, extra costs should be paid for redesigning channels and making them while the industrial dust collector can easily be moved from one place to another with lowest costs.

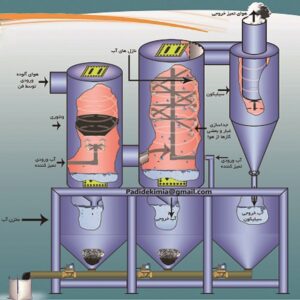

Components of dust collector:

Main components include filter bag, filter cleaning system (vibrator), high-pressure suction fan (2800 rpm), hopper or dust collection tank with fast system and simple sealing, control panel, and air inlets (that can have different diameters based on the need).

This method is low cost as it does not need auxiliaries, compressors, or air tanks to supply air to the solenoid valve.

Considering the experiences of Sepahan MAPNA Engineering & Equipment Manufacturing Company in similar projects, the company is capable of supplying and manufacturing this product.

Application of industrial dust collector in various industries:

- Aerospace industry

- Workshops where cars are repaired

- Workshops that produce (kitchen) cabinets

- Industries that produce and process chemicals

- Industries affiliated with electronics

- Glass production

- Laboratories

- Industries that work with metals

- Paper production

فارسی

فارسی Français

Français العربية

العربية